COLUMBIA GRAFONOLA REGENT

Directions for Operating

form 1072-2

Directions for Operating

form 1072-2

Click image above to

download pdf (940 k)

download pdf (940 k)

Records consist of flat discs, upon the surface of which sounds have been recorded by zig-zag lines. The spring motor drives the turn-table, which carries the record, at a uniform speed. The needle follows the lines of the record, and, by transferring its motions to the diaphragm, causes the latter to vibrate and reproduce the same sound-waves by which the record was originally made. For true-to-life reproduction, use Columbia Double-Disc Records. They give superior tone and volume, and last twice as long as others. All the newest and best music is added to the list monthly.

Place winding-crank through hole in the drawer and screw into engagement with winding-shaft.

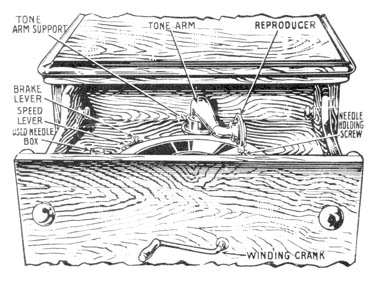

To attach reproducer to tone-arm, place needle-holder in line with the tone-arm, (so that pin in tone-arm will enter slot in reproducer), press reproducer close against tone-arm and rotate reproducer to the left (that is, in such direction that needle-holder will first move up) as far as it will go, when it will be in the position shown in the cut. To remove reproducer from the tone-arm, reverse this operation.

Wind motor by turning crank to right. Wind fully, but be careful not to overwind.

Insert needle, blunt end first, in needle-holder as far as it will go. Fasten with needle-holding-screw.

Place record on turn-table; start motor by moving brake-lever toward letter "S" on the graduated plate, as far as it will go; rest needle, gently, on the outer edge of the record, on the side of the center-pin nearest the winding-crank. The reproduction of the record will then commence.

To increase or diminish the volume of sound, open or close the tone-control shutters which are at the end of the table opposite the drawer.

Speed is regulated by the speed regulator. Moving the lever toward the letter "F" increases the speed; moving it toward the letter "S" decreases the speed. If the speed is too fast, the pitch will be too high and the time too rapid; if too slow, the pitch will be too low and the time too slow.

The speed at which Columbia records should be played is eighty revolutions per minute.

A new needle should be used for each reproduction. This is important; if it is not done, the records will be damaged. Use only Columbia needles. They are made to give various degrees of volume - loud, medium, or soft; and are least wearing on records.

OILING

Occasionally oil each bearing.

The spring motor is accessible, for this purpose, by raising the top board of the cabinet, to which it is attached. Before doing this, remove the turn-table by lifting straight up - care being taken to apply equal pressure at both sides; also remove the winding-crank and the screws which fasten down the round board. Oil liberally and frequently the felt pieces which contact with the friction-disc of the governor. The motor may not operate properly if these parts are allowed to become dry. Special attention should be given to the oiling of the two bearings of the winding-shaft in the motor frame. Also, a drop of oil should occasionally be placed on the inside of the metal part attached to the cabinet, through which the winding-crank passes. A paste made of oil and graphite is excellent for the teeth of the gears. If graphite is not at hand, oil alone may be used; but it is not as good for this purpose as the mixture.

Use only thin oil, of good quality, and of a kind which will not gum. This company furnishes oil especially adapted for its instruments.